In industrial and commercial work, surface preparation is more than just a first step, it’s the key to long-lasting results. Whether you’re coating steel, sealing concrete, or restoring old machinery, the surface has to be clean, strong, and ready to bond. That’s where shot blasting comes in.

Shot blasting is a fast, efficient, and highly effective way to remove rust, paint, and debris while creating a textured surface that new coatings can grip onto.

In this blog, we’ll break down what shot blasting is, how it works, why it’s better than other methods, and when to use it. Let’s get started.

What is Shot Blasting?

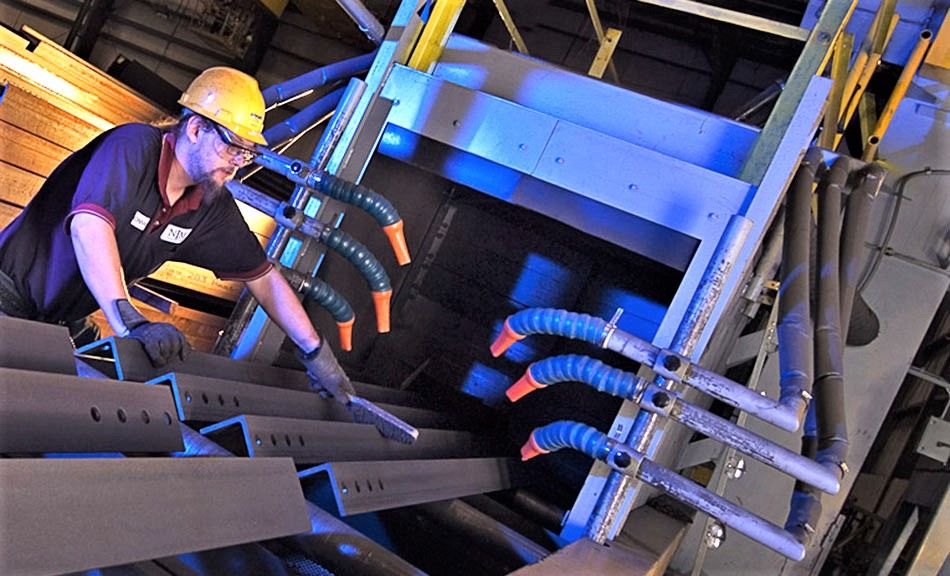

Shot blasting is a powerful surface preparation method that uses tiny metal pellets (called steel shot) to clean, smooth, or texture a surface. Unlike sandblasting, which relies on compressed air, shot blasting works by using centrifugal force. The machine spins a wheel at high speeds, flinging the steel shot at the surface to blast away dirt, paint, rust, or coatings.

This process is commonly done with wheel blast machines for large-scale jobs or portable shot blasters for floors and smaller areas. Blasting not only cleans but also profiles the surface, which makes it ideal for preparing concrete or metal before coatings are applied. It’s fast, efficient, and highly effective, which is perfect for when you need a clean, bond-ready surface.

How Does Shot Blasting Work?

Shot blasting is a fast, powerful way to clean and prepare surfaces, but how does it actually work? The process starts with a machine that uses a high-speed rotating wheel to hurl thousands of tiny metal beads, called steel shot, onto the surface. These pellets strike with serious force, breaking up rust, peeling off old paint, removing grease, and even stripping away old coatings.

As the abrasive shot hits the surface, it cleans, but it also roughens or textures it. This is key for projects where you plan to apply paint, sealants, or epoxy coatings. That rough profile helps new layers stick better and last longer.

Blasting is widely used on concrete, steel, and other tough surfaces. It’s dust-controlled, chemical-free, and much faster than traditional hand-scraping or sanding. This makes it the go-to choice for anyone who needs a clean, bond-ready surface in less time.

Benefits of Shot Blasting

Shot blasting is a method that offers a long list of benefits. First, it’s fast and efficient, blasting away years of buildup in a fraction of the time it would take by hand. Whether you’re dealing with rust, grime, or stubborn old coatings, shot blasting powers through it with ease.

It also prepares the surface perfectly for whatever comes next, whether that’s paint, epoxy, or a sealer. The textured profile it leaves behind helps coatings stick better and last longer, which means fewer issues down the road.

And unlike chemical strippers or acid treatments, blasting is eco-friendly. It uses no harsh chemicals and produces minimal dust when paired with the right equipment.

Plus, it saves on labor costs by getting the job done faster and more consistently. You get a cleaner, more even surface, every time.

When to Use Shot Blasting

Shot blasting is a go-to solution for heavy-duty surface prep, and for good reason. It’s tough, reliable, and works across a wide range of materials and industries. Wondering when to use it? Here are some of the most common and effective applications:

- Concrete Floors: Before you apply epoxy coatings or sealers, concrete needs a clean, textured surface to ensure proper adhesion. Blasting removes old coatings, oils, and debris while creating a profile that helps your new surface last.

- Steel Surfaces: Rust, mill scale, and old paint can ruin a coating job. Shot blasting strips these away efficiently, leaving the steel clean and ready for priming or painting.

- Roadways and Bridges: Blasting improves surface texture, which helps with traction and skid resistance; a must for safety in high-traffic areas.

- Industrial Equipment: Over time, machines get coated in grease, grime, and rust. Shot blasting not only cleans them up but can extend the life of your equipment with proper maintenance.

- Shipyards and Marine Structures: Saltwater environments are tough on metal. Blasting removes heavy rust and old marine coatings, preparing ships, docks, and rigs for a fresh layer of protection.

No matter the job, shot blasting delivers results that are clean, consistent, and built to last.

Shot Blasting vs. Other Methods

When it comes to surface prep, shot blasting stands out from the crowd. Unlike sandblasting, which uses compressed air, shot blasting is cleaner and more controlled. Compared to acid etching, it’s safer (no harsh chemicals) and creates a stronger surface profile. While grinding smooths surfaces, it doesn’t clean as deeply or prep for coatings as well. Blasting is the best choice when you need fast, eco-friendly, and effective results, especially for prepping concrete or metal for long-lasting coatings. It’s the efficient, no-nonsense method that delivers both cleaning power and bonding strength.

Choose Norfolk Iron & Metal for High-Quality Shot Blasting

At Norfolk Iron & Metal, we know that proper surface preparation is critical to long-lasting results. That’s why we offer professional shot blasting services tailored to your project’s specific needs. Our team has the tools and experience to deliver clean, consistent, and coating-ready surfaces every time.

Not sure if shot blasting is the right fit? Let our experts assess your project and recommend the best prep method. Contact us today for reliable, high-quality surface preparation that sets the foundation for success.

Follow Us